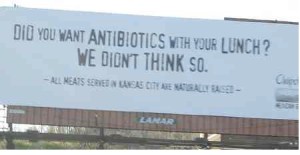

I’ve been a long-time proponent that those farmers, processors and retailers that are really good at microbial food safety should be able to market such evidence directly to consumers.

This has nothing to do with food safety being a non-competitive issue, or whatever else industry types claim: It has everything to do with providing a market-based incentive for those in the farm-to-fork food safety system to brag about what they do.

This has nothing to do with food safety being a non-competitive issue, or whatever else industry types claim: It has everything to do with providing a market-based incentive for those in the farm-to-fork food safety system to brag about what they do.

There are good actors, there are bad actors: if trade associations were really concerned about their customers barfing, they’d stop saying everyone cares about food safety and support efforts to make such information readily available at retail.

But such microbiologically-safe claims are only valid with publicly available data: And there’s no such thing as no risk – or no Salmonella.

As that foodborne Salmonella infections in Denmark reached a historic low, some Danish processors are, according to Steve Sayer of Meatingplace.com, claiming on labels their chicken is Salmonalla-free.

Right, is a retail package containing raw skinless/boneless chicken that was recently purchased in Denmark (DK) Europe.

The labeling on the package is claiming to Danish consumers (where there’s an orange drawing of a chicken within a round circle): “Dansk Salmonelllafri Kylling,” when translated means – “Danish salmonella-free chicken.”

The DK packer is Rose Packing that claims their chicken is “salmonella free” on their website.

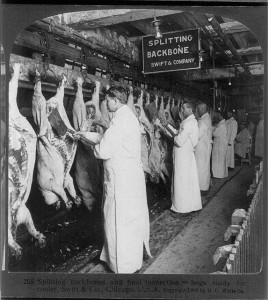

The long and winding road that the Danes labored to lowering salmonella within their hatcheries, layer hens, broiler chickens and eggs are impressive.

In 2015 a total of 925 salmonella infections were reported among Danes, which is equivalent to 16.2 infected cases per 100,000 inhabitants. This is the lowest number of salmonella infections since 1988, which is the first year from which researchers at the National Food Institute have used data to map the sources of foodborne salmonella infections.

2015 is also the first year since the introduction of the salmonella source account that Danish eggs have not caused illness. There have also been no registered cases of infection due to Danish chicken meat, which has been the case in four of the previous five years.

“The good results regarding Danish eggs and poultry are very encouraging. However, salmonella still constitutes a risk. Therefore it is important to maintain the preventive measures that researchers, governments and industry have jointly implemented over the years to ensure that salmonella is kept out of Danish products,” Senior Scientific Officer Birgitte Helwigh from the National Food Institute says.

Campylobacter continued to be the cause of most of the registered foodborne infections in Denmark in 2015 with 4,348 cases of illness. This represents a 15% increase from 2014 and is the highest number of cases ever recorded.

Improvements in the reporting system and changes in diagnostic methods mean that more cases of illness are registered than in the past. Therefore it is unclear whether more people actually got a campylobacter infection in 2015 compared to previous years.

Improvements in the reporting system and changes in diagnostic methods mean that more cases of illness are registered than in the past. Therefore it is unclear whether more people actually got a campylobacter infection in 2015 compared to previous years.

In 2015, only 39 foodborne disease outbreaks have been registered. This is the lowest number of outbreaks since a nationwide database for food and waterborne disease outbreaks was established almost ten years ago. A total of 1,233 people have become sick in connection with the 39 outbreaks.

As in previous year norovirus was the leading cause of outbreaks (42%).

“Particularly in the recent past, Americans have been overwhelmed by food safety scares. People are very concerned and having some certification on the foods they buy can appease some of those fears.”

“Particularly in the recent past, Americans have been overwhelmed by food safety scares. People are very concerned and having some certification on the foods they buy can appease some of those fears.”