bites.ksu.edu and barfblog.com are complimentary and comprehensive resources for those interested in microbial food safety – the things that make people barf.

Too many people get sick each year from the food and water they consume. bites and barfblog are designed to inform and engage people in dialogue about food-related risks,  controls and benefits, from farm-to-fork.

controls and benefits, from farm-to-fork.

For rapid, relevant and reliable food safety news, subscribe to barfblog.com and follow us on twitter; for a daily, or twice-daily summary, including barfblog.com posts, subscribe to bites-l at bites.ksu.edu.

Dr. Doug Powell of Kansas State University, and associates, provide credible, current, evidence-based information on food safety and make it available through multiple media. Sources of food safety information include government regulatory agencies, international organizations such as the World Health Organization (WHO) and the Food and Agriculture Organization of the United Nations (FAO), peer-reviewed scientific publications, recognized experts in the field and other sources as appropriate.

barblog.com

barfblog.com is where Drs. Powell, Chapman, Hubbell and assorted food safety friends offer evidence-based opinions on current food safety issues. Opinions must be evidence-based — with references — reliable and relevant. The barfblog authors edit each other, often viciously.

Twitter and Facebook

Breaking food safety news items that eventually appear in bites or barfblog are often posted on Twitter and Facebook for faster public notification.

Infosheets

Food safety infosheets are designed to influence food handler practices by utilizing four attributes culled from education, behavioral science and communication literature:

• surprising and compelling messages;

• putting actions and their consequence in context;

• generating discussion within the target audiences’ environments; and

• using verbal narrative, or storytelling, as a message delivery device.

Food safety infosheets are based on stories about outbreaks of foodborne illness sourced from bites and barfblog and include the following: discussion of a foodborne  illness outbreak; discussion of background knowledge of a pathogen (including symptoms, etiology and transmission); food handler control practices; and emerging food safety issues. Food safety infosheets also contain evidence-based prescriptive information to prevent or mitigate foodborne illness related to food handling.

illness outbreak; discussion of background knowledge of a pathogen (including symptoms, etiology and transmission); food handler control practices; and emerging food safety issues. Food safety infosheets also contain evidence-based prescriptive information to prevent or mitigate foodborne illness related to food handling.

bites-l listserv

The bites.ksu.edu listserv is a web-based mailing list that provides information about current and emerging food safety issues, gathered from journalistic and scientific sources around the world and condensed into short items or stories that make up the daily postings. The listserv has been issued continuously since 1993 and is distributed daily via e-mail to thousands of individuals worldwide in academia, industry, government, the farm community, journalists and the public at large.

The listserv is designed to:

• convey timely and current information for direction of research, diagnostic or investigative activities;

• identify food risk trends and issues for risk management and communication activities; and

• promote awareness of public concerns in scientific and regulatory circles.

The bites listserv functions as a food safety news aggregator, summarizing available information that can be can be useful for risk managers in proactively anticipating trends  and reactively address issues. The bites editor, Dr. Powell, does not say whether a story is right or wrong or somewhere in between, but rather that a story is available today for public discussion; barfblog is where contributors express their evidence-based opinions on food safety issues.

and reactively address issues. The bites editor, Dr. Powell, does not say whether a story is right or wrong or somewhere in between, but rather that a story is available today for public discussion; barfblog is where contributors express their evidence-based opinions on food safety issues.

Research

Researchers associated with bites and barfblog conduct an array of food safety research, including:

• effectiveness of food safety messages and media in public discussions of food safety issues, such as the risks of listeria to pregnant women, legislation related to raw milk, public availability of restaurant inspection data, and the safety of fresh produce, are evaluated through qualitative and quantitative methods;

• observational research methodologies are used to quantify individual food safety behaviors from farm-to-fork, to enhance handwashing compliance, thermometer use, food packaging information and interventions that can reduce the number of people that get sick from the food and water they consume; and,

• evaluation of food safety policy and alternatives.

Teaching

• A graduate program in food safety risk analysis – including food safety, language, culture and policy — is being developed and will include distance-education.

• Courses are currently taught in food safety risk analysis, and food safety reporting.

Information

• Dr. Powell is the publisher and editor of bites and barfblog. Dr. Ben Chapman of North Carolina State University is the assistant editor.

• bites and barfblog are produced by a diverse team of secondary, undergraduate and graduate students as well as professionals who create multilingual and multicultural food safety and security information, including weekly food safety information sheets, and multimedia resources.

• Research, educational and journalistic opportunities are available for secondary, undergraduate and graduate students through bites.ksu.edu and barfblog.com.

Dr. Powell, a professor of food safety at Kansas State University, is the author of 42 peer-reviewed journal articles, 10 peer-reviewed book chapters and 1 peer-reviewed .jpg) book. His cv is available at http://bites.ksu.edu/powell_cv.

book. His cv is available at http://bites.ksu.edu/powell_cv.

Links

bites and barfblog may include links to other sites, which are provided as a convenience and as an additional access to the information contained therein. bites and barfblog are not responsible for the content of any other sites or any products or services that may be offered through other sites.

Accuracy, Completeness and Timeliness of Information on the Site

The bites and barfblog folks strive to provide accurate, complete and current information. The materials on this site are provided for general information only, and any reliance upon the material found on this site will be at your own risk. We reserve the right to modify the contents of the site at any time.

For more information, please contact us.

verdict in an edible oil case that has shaken confidence in locally-produced food products.

verdict in an edible oil case that has shaken confidence in locally-produced food products.

.jpg) essentially recalled everything that producer has put out."

essentially recalled everything that producer has put out.".jpg) through their DNA fingerprints.

through their DNA fingerprints. extension specialist at North Carolina State University will conduct the workshop at the Dubai International Convention and Exhibition Centre.

extension specialist at North Carolina State University will conduct the workshop at the Dubai International Convention and Exhibition Centre. safety hotline that was established at the University of Guelph. Other prevalent themes were specific products and brands, food preservation, non-food safety topics and emerging issues.

safety hotline that was established at the University of Guelph. Other prevalent themes were specific products and brands, food preservation, non-food safety topics and emerging issues.

controls and benefits, from farm-to-fork.

controls and benefits, from farm-to-fork. illness outbreak; discussion of background knowledge of a pathogen (including symptoms, etiology and transmission); food handler control practices; and emerging food safety issues. Food safety infosheets also contain evidence-based prescriptive information to prevent or mitigate foodborne illness related to food handling.

illness outbreak; discussion of background knowledge of a pathogen (including symptoms, etiology and transmission); food handler control practices; and emerging food safety issues. Food safety infosheets also contain evidence-based prescriptive information to prevent or mitigate foodborne illness related to food handling..jpg) book. His cv is available at

book. His cv is available at

.jpg) regulations and inspections, or their food safety culture, is often overlooked.

regulations and inspections, or their food safety culture, is often overlooked.

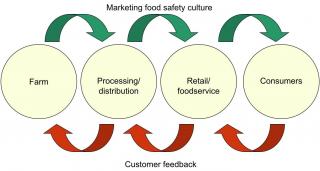

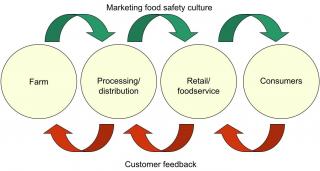

(1).jpg) However, it remains a challenge to compel food producers, processors, distributors, retailers, foodservice outlets and home meal preparers to adopt scientifically validated safe food handling behaviors, especially in the absence of an outbreak.

However, it remains a challenge to compel food producers, processors, distributors, retailers, foodservice outlets and home meal preparers to adopt scientifically validated safe food handling behaviors, especially in the absence of an outbreak. • stay up-to-date on emerging food safety issues;

• stay up-to-date on emerging food safety issues;.jpg) encouragement and enforcement to foster a food safety culture; and use technology to be transparent – whether it’s live webcams in the facility or real-time test results on the website – to help restore the shattered trust with the buying public.

encouragement and enforcement to foster a food safety culture; and use technology to be transparent – whether it’s live webcams in the facility or real-time test results on the website – to help restore the shattered trust with the buying public.(1)(1).jpg) demonstrable way. In an organization with a good food safety culture, individuals are expected to enact practices that represent the shared value system and point out where others may fail. By using a variety of tools, consequences and incentives, businesses can demonstrate to their staff and customers that they are aware of current food safety issues, that they can learn from others’ mistakes, and that food safety is important within the organization. The three case studies presented in this paper demonstrate that creating a culture of food safety requires application of the best science with the best management and communication systems, including compelling, rapid, relevant, reliable and repeated food safety messages using multiple media.

demonstrable way. In an organization with a good food safety culture, individuals are expected to enact practices that represent the shared value system and point out where others may fail. By using a variety of tools, consequences and incentives, businesses can demonstrate to their staff and customers that they are aware of current food safety issues, that they can learn from others’ mistakes, and that food safety is important within the organization. The three case studies presented in this paper demonstrate that creating a culture of food safety requires application of the best science with the best management and communication systems, including compelling, rapid, relevant, reliable and repeated food safety messages using multiple media.